All the files are open source on Tinkercad and the .stl's are available at Thingiverse.

|

I had a little bit of free time after the Thanksgiving Holiday so I created a few 3D printer projects. One was an Advent Calendar Christmas Tree. This took all the space my Davinic 3D printer could support and took two print runs to finish it. The blocks slide out and can be flipped so the number is hidden. Everyday you take one number and flip it until only #1 is left and that is Christmas Eve. The design was done in Tinkercad and the full build is shown on my YouTube Channel and in the video below. I did it as a count-down to 1 but you can reverse the blocks and make it show the calendar day so place the #1 in the bottom and the #24 at the top. The blocks slide out easily and can be pushed from the back. At some point I could print one of these and put LEDs on the blocks so a Microcontroller can do the count-down automatically. All the files are open source on Tinkercad and the .stl's are available at Thingiverse.

1 Comment

I've returned as a columnist for Nuts & Volts Magazine. My column titled "Getting Started with 3D Printing" started today in the December issue of Nuts and Volts Magazine. I wrote the "Getting Started with PICs" column from 2006 thru 2009 and it ended for reasons beyond my control but I'm happy to be back. The idea behind the column is to help anybody just getting started with 3D printing with tips and tricks that I've learned or will soon learn as I get deeper into 3D printing myself. There is so much to learn beyond downloading a thingiverse file and printing it. And with the various low cost printers available, I thought the timing was right to help others get started. If you are a regular reader of this blog though, you know I've been writing about my 3D printer adventures for some time. But the N&V column is written for the electronics hobbyist who wants to design that custom case or special mount for their electronic project. There is so much 3D printing can offer and I feel like it's just getting started. Reminds me of the early days of the PC. I think we are still waiting for that killer app or killer print that will make everybody want a 3D printer the same way Visicalc did for the early PCs. I've also added some new videos to my YouTube Channel that weren't posted here. I'm trying to separate this blog and the YouTube Channel a bit because I still want to help those who still are looking for my help with their electronics hobby. If you are a subscriber to N&V then check out the column. If not, maybe find it on the newsstand and see if it something you'd like to read. I hope to keep that column running for a long time.

I recently bought a CLOUDBIT kit from littleBits and it's expected to arrive in a few days. What interested me the most is the application they advertise for a doorbell switch that will send you a text message when the switch is pressed. The idea is to indicate someone is at your door even if you aren't home at the time. I found this idea interesting because there are so many projects where I'd like to receive a text message indicating something timed out or a process completed. That way I don't have to sit and monitor it or check back often. One such process is 3D prints. When a print is done I'd like to receive a text message letting me know. I've read about multiple different modules that allow you to connect to the internet but I found most of them very confusing. That was until I found littleBits. The module has a linux computer on-board so this is more than just a little plug and play module, it's a very complicated module that reduces the internet access down to a high/low signal.

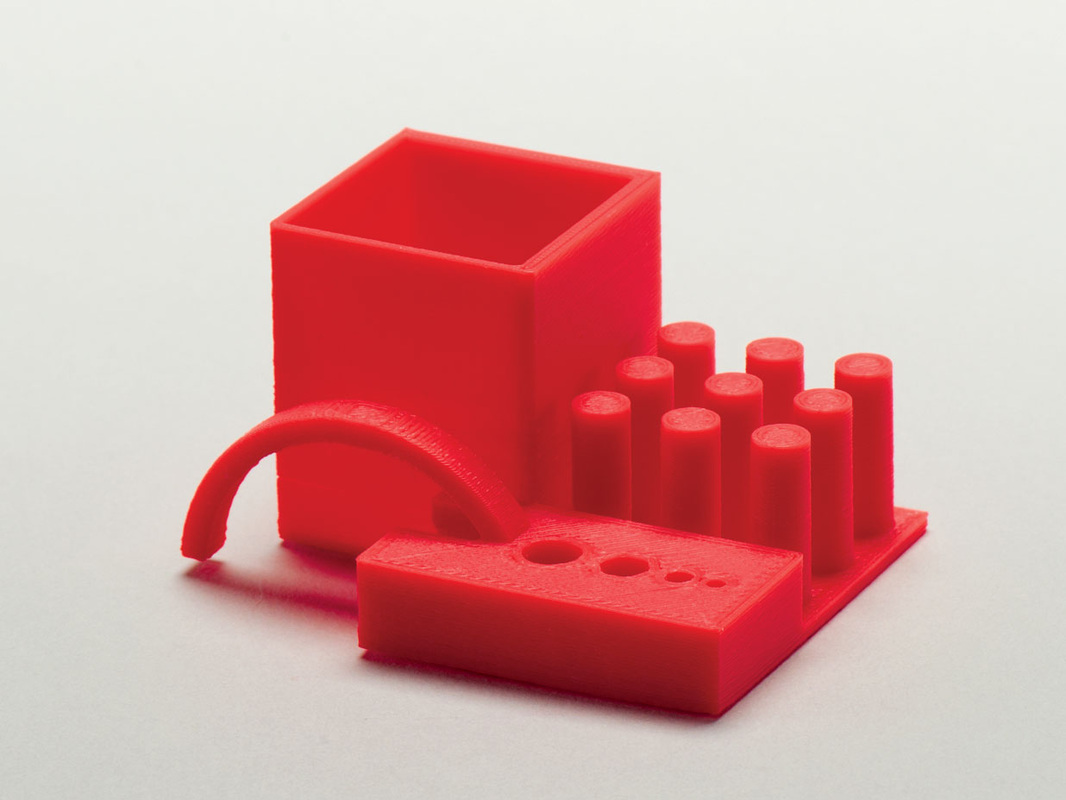

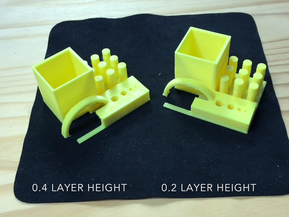

The module relies on an internet service called IFTTT which stands for If That Then This. I've visited the site and it appears to be some kind of scripting language setup that allows you to easily create actions based on various inputs and outputs all connected through the internet. I hope to understand it a lot better when I get the CLOUDBIT running on my Davinci 3D printer so stay tuned if you have any interest in this type of project. In the Make Magazine November 2012 issue, they ran a 3D print competition with many of the existing available 3D printers. They ran a test print that had some unique features. It had an unsupported arch, round and hex holes, posts and a box with walls of different thickness. Then each printer created it at default settings. I decided to try the same print on my Davinci 3D printer and the results were great. I printed with and without supports so the arch failed in the non-support but everything else was fine. It's still not clear to me if support would have been permitted or not. I produced a YouTube video showing the steps and the results. The .STL file is available on Thingiverse for anybody to try. I printed it at different levels or 0.2 layer and 0.4 layer. The default on my XYZware is 0.4 layer, 10% fill and standard shell and standard speed. The support was low fill. Both the 0.2 and 0.4 looked great. It's true that the Davinci had two years of development over the printers in the magazine, since it wasn't released until two years later, but a sub $500 printer wasn't available back then either. So I'm once again sold on the quality of this Davinci printer. |

Categories

All

Visit previous blog posts in the archives below.

Archives

February 2018

About ChuckChuck has been programming with PIC Microcontrollers since there were only five devices. Now there are over 700 and growing. He also has a lot of fun 3D printing designs using his Davinci 3D printer and TinkerCad software. In this series of blog posts and occasional videos on his YouTube Channel he tries to help you get started with electronics and 3D printing. Disclaimer |

RSS Feed

RSS Feed