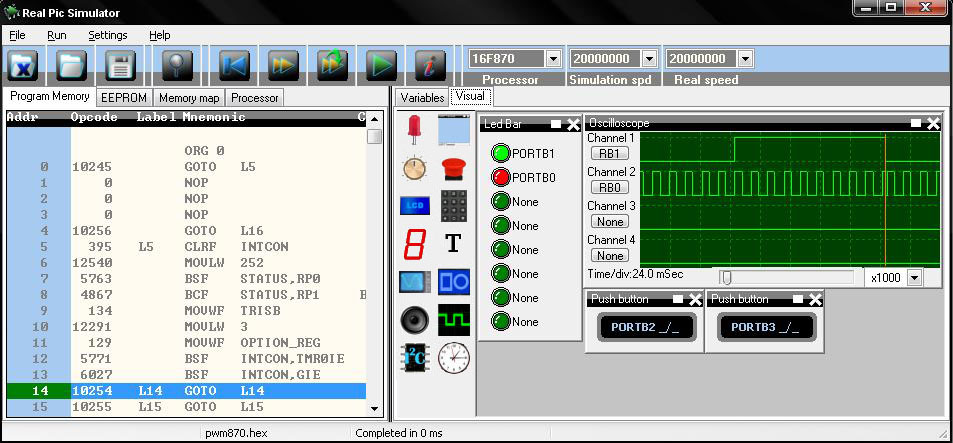

The simulator works with the .hex file created by the compiler of your choice and then allows you to run it on simulated electronic components. There are LEDs, switches, potentiometers, LCDs and more. Amazingly it also includes a graphic LCD based on the KS0108 chip. I created a Great Cow Basic project for that recently and had a hard time getting everything working correctly but after several hours had it working. I loaded that same .hex file in Real Pic Simulator and tested it on the graphic LCD and it displayed perfectly. I wish I had this before.

The GUI objects also includes an oscilloscope object which is more like a logic analyzer. There is also a function generator but I haven't tried that out yet so I'm not sure exactly how well that works.

Bottom line is, this tool works great with any PIC development package to give you a quick way to test typical circuitry blocks with code.

Check it out at:

http://digitalelectrosoft.com/pic-simulator

RSS Feed

RSS Feed