The kit has a lot of steps and it's not really a beginner kit but I was able to get it together and cut my first piece of wood. I had several mis-attempts because I had not setup the GRBL software properly. Inventables gave me the tip to check the settings and I found the error.

|

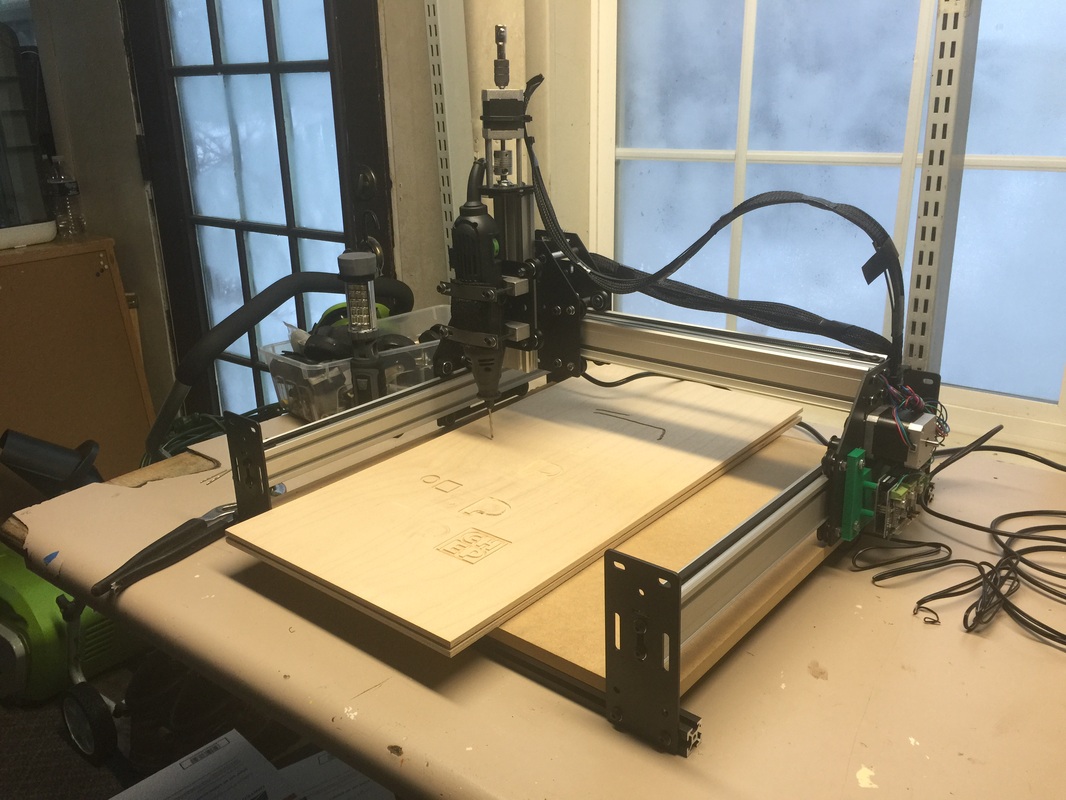

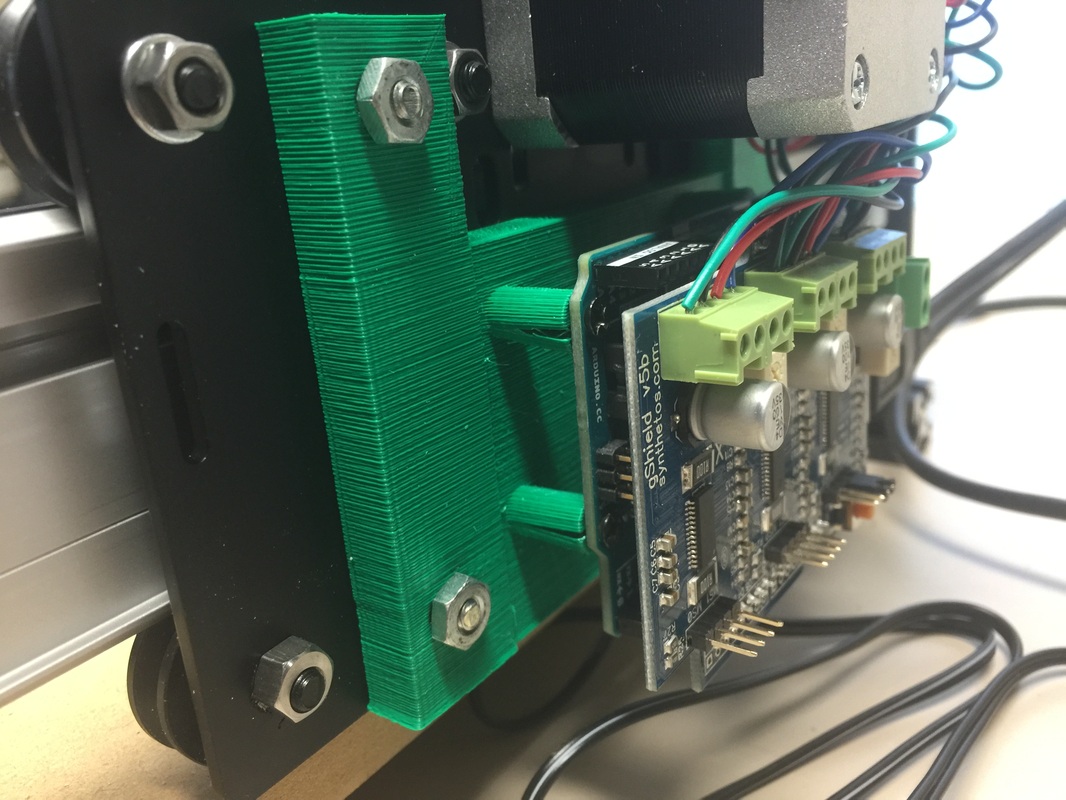

It's been a while since I updated my blog. I've been very busy in my shop and my YouTube Channel continues to grow approaching 1000 subscribers. During all this I was able to put in the hours needed to complete my Shapeoko 2 that I purchased around Christmas. There was a $100 off sale and I bought one. The kit has a lot of steps and it's not really a beginner kit but I was able to get it together and cut my first piece of wood. I had several mis-attempts because I had not setup the GRBL software properly. Inventables gave me the tip to check the settings and I found the error. I was finally able to cut out my new CHEP logo and it did a fine job. I need to make a visit to Harbor Freight tools to see what bits I can get for this thing. I want to get some small blade bits so I will be able to cut out circuit boards. My goal is to find a way to cut out 2 layer boards from ExpressPCB files. I can get the gerbers through CopperConnection and then I'll try to find a Gerber to G-Code converter. I know it exists but I just haven't put the time to fully investigate the steps plus I didn't have the the CNC tool to test it all out until now. Learning to cut circuit boards is just one thing on my list of things to do. I also 3D printed a base to mount the Arduino board to the frame. If you look close you can see that the mounting bosses split. I have a fix I want to try so that will be part of a future YouTube video. If you have one of these Shapeoko's and have some tips for me, I'm all ears.

1 Comment

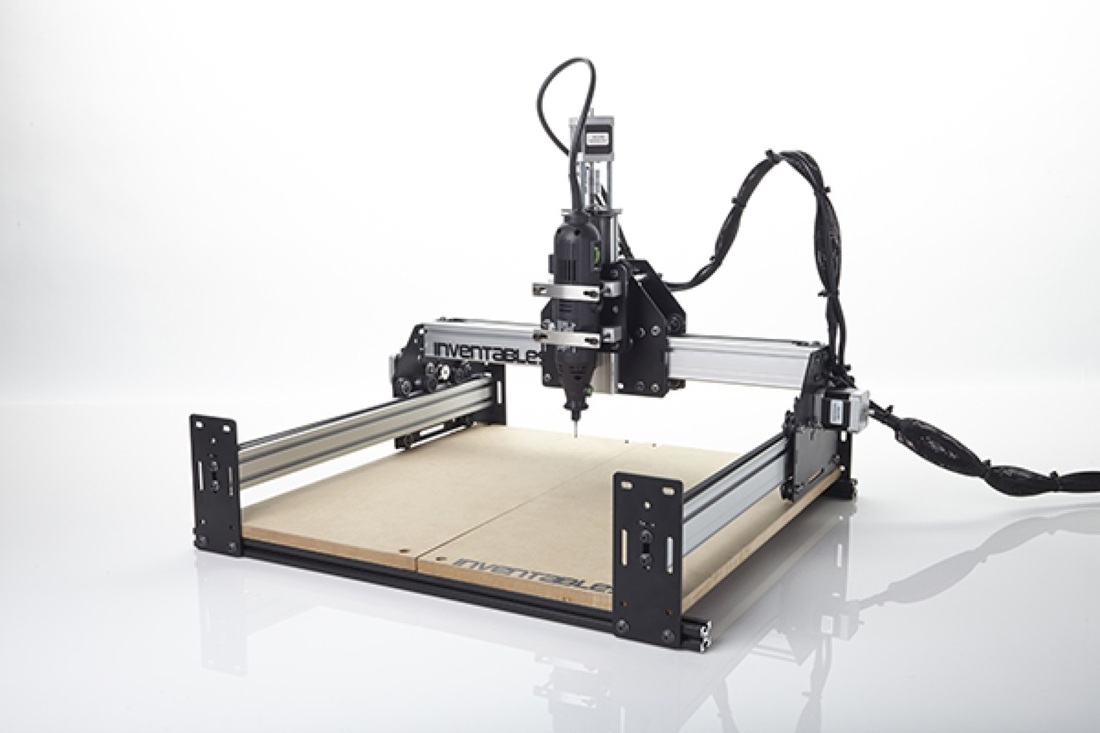

For Christmas I bought myself a Shapeoko 2 CNC machine. I'm still waiting for it to arrive but my own CNC machine is something I've been dreaming about for a long time. I've watched CNC machines come down in price and thought about getting a cheap Chinese-built unit on EBAY but the software was always the hangup. They all seemed to use Mach 3 software which required a computer with a parallel port. I had two computers that fit the requirement but they both crashed in the past year so I preferred to get a USB controlled unit. I also wanted an easy software for creating the design. When the Inventables.com guys released the Easel software that also controlled their Shapeoko 2 CNC kit, I was sold. I saw them at the Detroit MakerFaire and saw the Easel software in action. I wrote about it in aprevious post. Well over the holiday, I saw the Shapeoko 2 was on sale for $100 off. This is because the new Shapeoko 3 was coming out soon. Shapeoko 2 had everything I wanted so I bought it while on sale. I received an email that my package was shipped and they are in Chicago and I'm outside Detroit so it shouldn't take long to get here. I'm told it takes about 10-12 hours to put it all together so I'll be doing that over a period of time. I also plan to time lapse record it for my YouTube channel. To get a CNC machine with software for around $550 is something I hoped I'd see but never thought it would happen this soon. I plan to build things that my 3D printer can't and find ways to combine CNC, 3D prints and Electronics to make some interesting projects. I just wish I had more time to play with all these great tools.

And best of all, if you have been following me for a while, you know I'm a really fan of 8-bit microcontrollers. I prefer PICs but most of all I prefer the simplicity of 8-bit. I've had people tell me that I'm crazy for not switching over to 32 bit but I'm still not convinced I need that extra horsepower for what I like to do; build electronic products. Well my 3D printer is 8-bit, and now so is my Arduino controlled CNC Shapeoko 2. Not to mention my lab full of 8-bit PIC boards and projects. Tell me again why I need to switch to 32 bit? I didn't have a booth MakerFaire - Detroit this year but, I spent the first day of the Faire checking things out. It's actually the first time I got to roam the place without having to rush back to my booth so its really the first time I've been able to enjoy everything MakerFaire - Detroit has to offer. My first major find was the guys from Easel. They produced a CNC drawing software that handles all the GCode creation as well, plus it sends it to a Shapeoko CNC cutter, all in one software application. And it's Free! They basically created for CNC cutting what TinkerCad does for 3D printing and more. I thought it was still in Beta mode but it has apparently been officially released per the Easel guys. And who was there checking it out at the same time I was? None other than Ben Heckendorn of the Ben Heck show. We were both bombarding them with questions but Ben got to try it out first so I just watched. It's really awesome. I plan to add a Shapeoko to my lab so I'll have both 3D printing and CNC capability. They were routing out a circuit board when I first walked up. At my 3rd MakerFaire in 2012, I had a Hot Wheels multi-lane track with a custom LED winner indicator at the finish. It had light sensors built into the track and would light an LED for the winner. It was a hit with the kids. Well I saw a new one at this years Faire that blew mine away. It used wooden cars and had timers for each lane. It was huge and extremely popular with the kids. It was built at the Maker Works makerspace in Ann Arbor Michigan but unfortunately it was so crowded I couldn't get any details on who made it or the electronics used inside. And finally, what would a trip to Maker Faire - Detroit be without a visit to the Star Wars booth. Every year they step it up. Storm Troopers as usual along with a Droid junk yard. I tried to get through everything at the Faire, which included so many 3D printers. There was just about every kind you could imagine, except for the Davinci 3D. I didn't see a single Davinci 3D printer (unless someone was hiding in a corner). I even talked to a few people about the Davinci and found many knew nothing about it. But I did get to compare the prints of all various printers and it was clear to me that the Davinci prints just as good as most of the printers costing far more.

3D printers have clearly taken over the Maker Faire. What was interesting is I saw very few electronics booths or Arduino booths other than the big Make Magazine tent. It appears that most of the electronics sellers with custom shields and boards that were at past Faires have either quit Maker Faire - Detroit or got sick of competing with the Make Tent. That is a shame because the first few years you could find just about any electronics you wanted. Raspberry PI was at a few booths but they were just showing something it could do. Arduino presence was not big either outside the Make Tent. Overall, I thought it was another great Maker Faire - Detroit. Outside the weather was hot but perfect. Inside the museum was cool and crowded. The fact that it's actually in Dearborn, not Detroit, at The Henry Ford and costs $28 to get in for the day makes it the most expensive Maker Faire I know of. But people still crowd the place. I continue to be amazed by the crowds that this Faire draws. It is well worth the trip if you get a chance. |

Categories

All

Visit previous blog posts in the archives below.

Archives

February 2018

About ChuckChuck has been programming with PIC Microcontrollers since there were only five devices. Now there are over 700 and growing. He also has a lot of fun 3D printing designs using his Davinci 3D printer and TinkerCad software. In this series of blog posts and occasional videos on his YouTube Channel he tries to help you get started with electronics and 3D printing. Disclaimer |

RSS Feed

RSS Feed