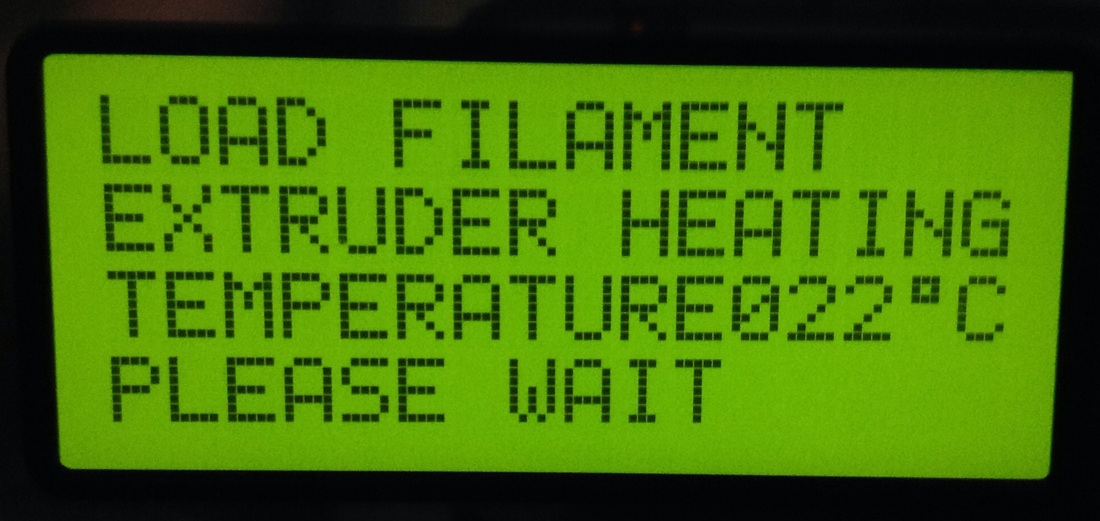

I have been running the software on a small NetBook Computer running XP but recently moved the printer to my office where I have a iMac running Maverick 10.9.3 operating system. The software from XYZ Printing was locking up so an email to the tech support got a quick response and a patch version to try. It improved but still had some issues that they are working on. I hope to get a new patch soon.

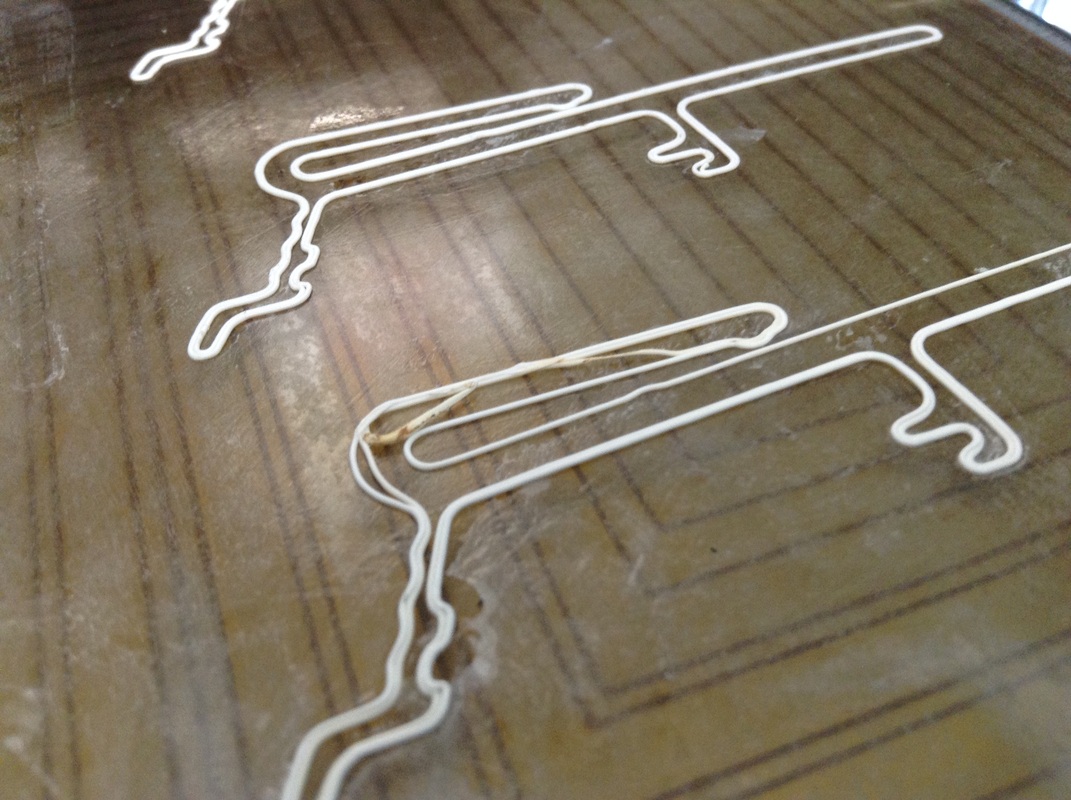

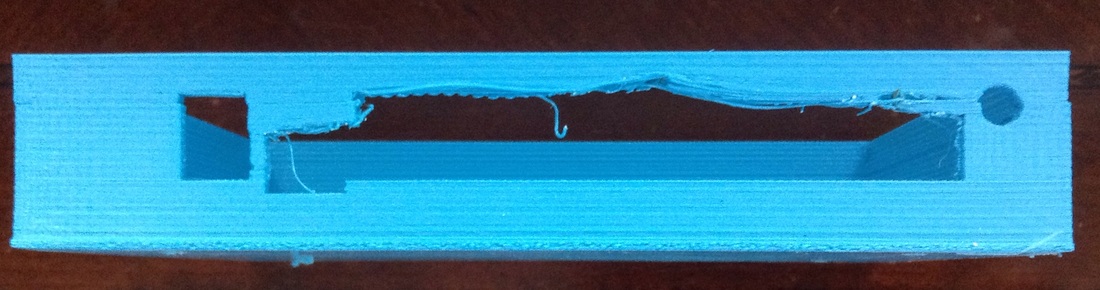

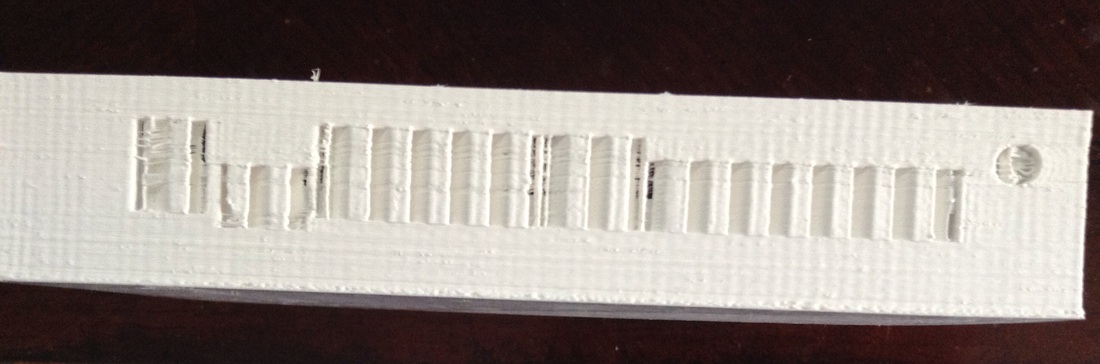

The loss of the test strip though is irritating as it results in prints that have the discolored defect built into the part as seen in the picture below.

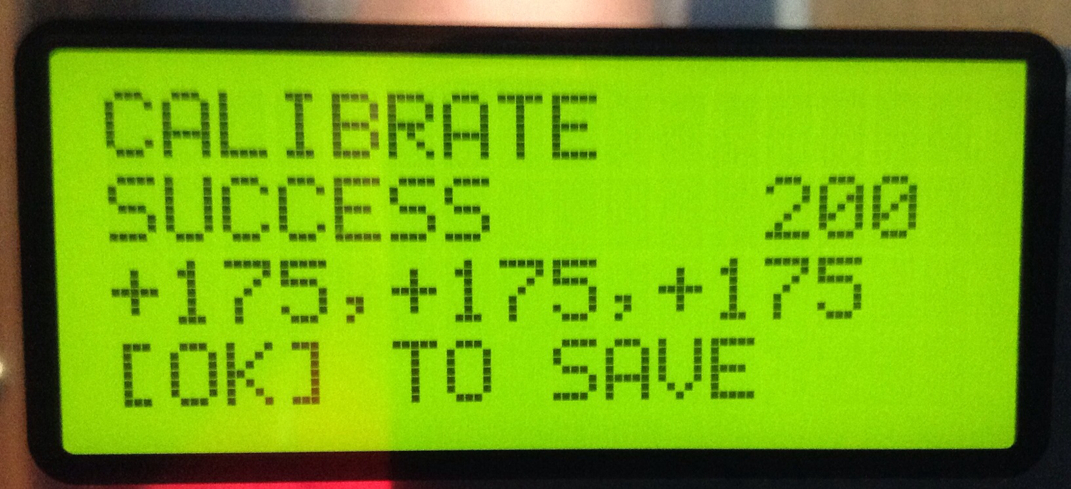

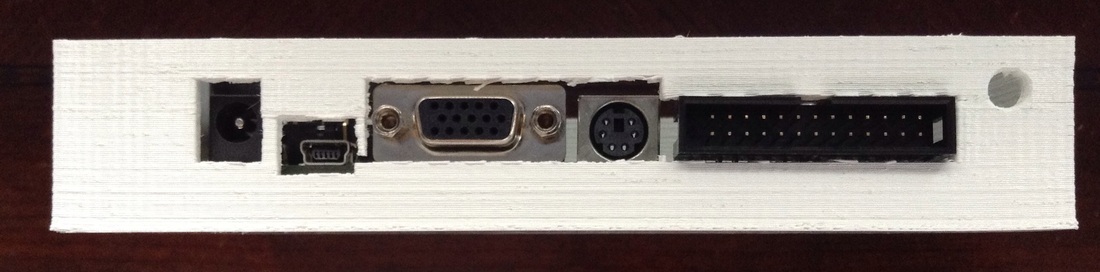

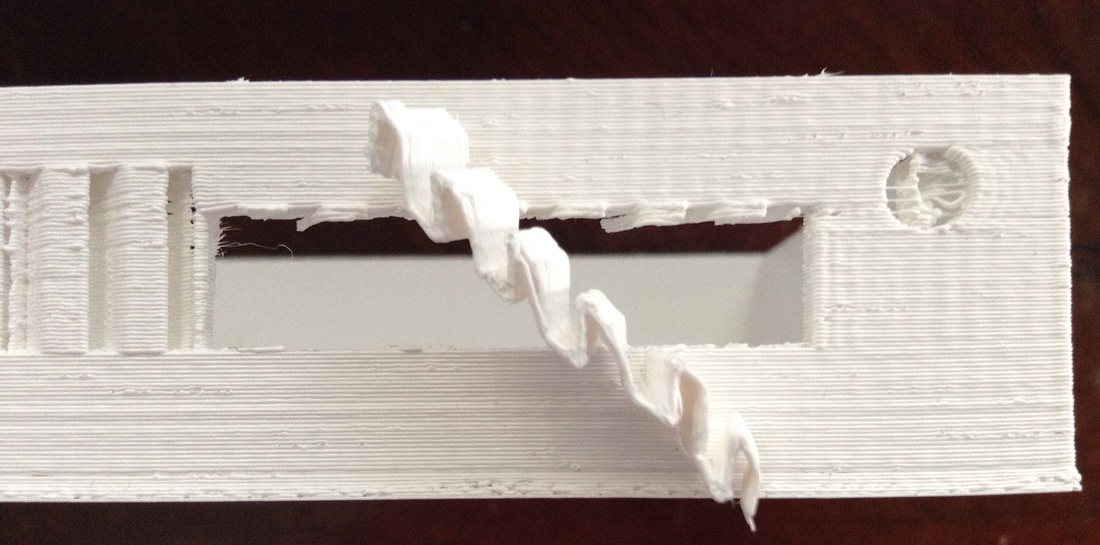

Below is a video of the Davinci laying down the first layer. You can see the bead just roll out and stick perfectly (other than the first few strips). I believe this is what you want to see after adjusting your heated bed to extruder nozzle clearance.

I also don't add the suggested stick glue to the platform as the heat of the bed and the heat of the plastic are enough to hold it. Frankly, I find the glue somewhat useless to be honest. The heated of the bed just melts it and the stickiness is limited at that point. A proper set bed seems to do the trick.

RSS Feed

RSS Feed