In the near future I want to 3D print a case for my PK2 programmer. That's for another post on another day.

|

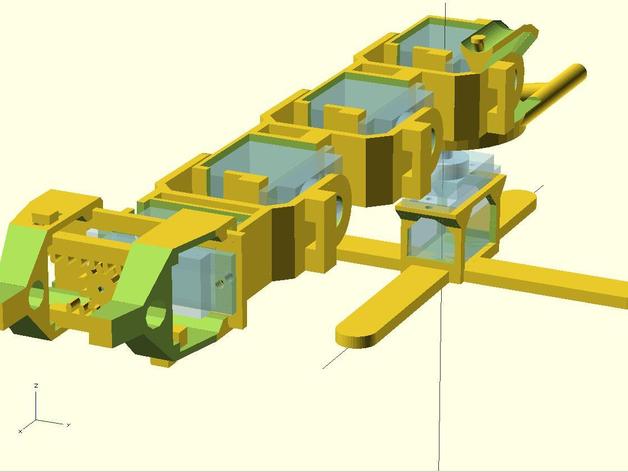

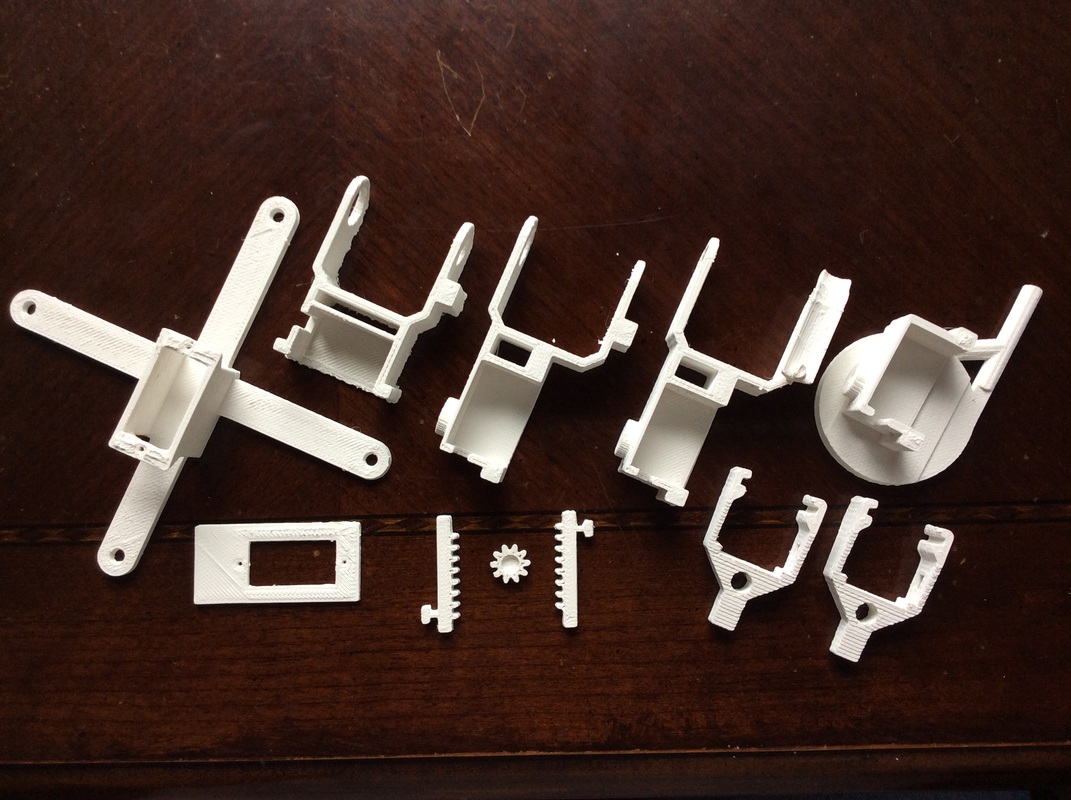

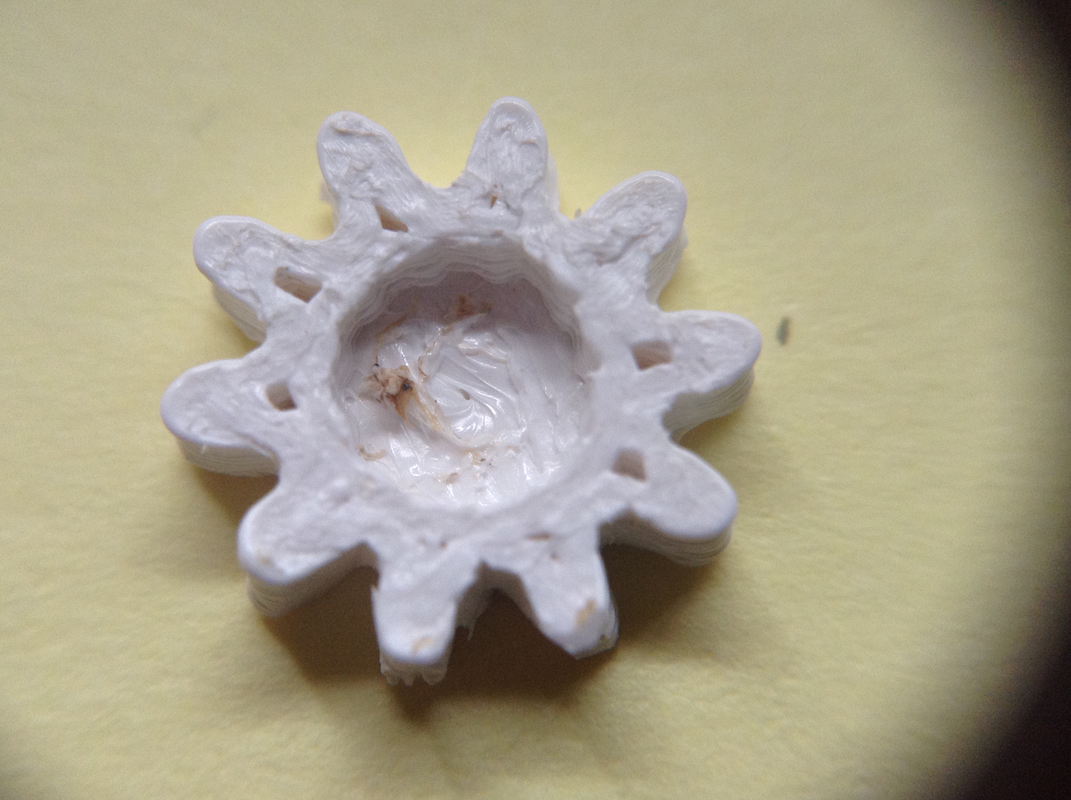

I was searching thingiverse and found a interesting micro robot arm from user Holgero. It uses 9G micro servos so its not real strong but I've been looking for a simple robot arm to control with CHIPINO or Maximite and this looked like a great option. So I printed the components one by one as you can see in the picture to the lower right. I ordered a set of servos from EBAY and as soon as they arrive I can assemble the arm. In the process of 3D printing these pieces on the Davinci 3D printer, I found that the "Excellent" setting worked the best. It uses a 0.2 level and 30% fill. A 50% fill is sometimes helpful but that is an advanced setting. The test of this came when I tried to print out the very small gear that drives the arm's gripper. I tried 0.2, 30% (Excellent), 0.2, 50% and 0.1, 50%. They are shown below. 0.2, 50% is on the left. 0.2, 30% is in the middle and 0.1, 50% is on the right. The 1% still needs to be trimmed but it had more stuff to trim than the other two. The 0.2, 30% in the middle should work fine but the 0.2, 50% has a better hole size to fit the servo shaft. There was a hole designed into the center for the servo screw but none of them printed it. Below are close-ups of the 0.2, 30% on the left and 0.2, 50% on the right. The 0.1 just wasn't worth the extra time or material. I frankly am convinced that the Excellent setting is the way to go for most prints. I'm still running off the original cartridge that came with the printer. I've printed a lot of small stuff but I'm still amazed how long it has lasted. It originally said I have 120 m of 120 m max material so that doesn't make much sense since I started with 300 grams of material. But I've printed the whole robot arm and it still says 120 m so I'm not sure its accurate. I'll keep printing until it runs out. I ordered more colors and they arrived yesterday so I'm all set for plastic. Each color is 600 grams so twice as much as I've started with. I may try printing in two color by pausing the print, swapping cartridges and then finish with the second color. I'll see if that will work. I'm also looking at design software. Sketchup is popular but I've played with tinkercad in the past as well so I may try that now that I can actually print the result.

In the near future I want to 3D print a case for my PK2 programmer. That's for another post on another day.

0 Comments

Leave a Reply. |

Categories

All

Visit previous blog posts in the archives below.

Archives

February 2018

About ChuckChuck has been programming with PIC Microcontrollers since there were only five devices. Now there are over 700 and growing. He also has a lot of fun 3D printing designs using his Davinci 3D printer and TinkerCad software. In this series of blog posts and occasional videos on his YouTube Channel he tries to help you get started with electronics and 3D printing. Disclaimer |

RSS Feed

RSS Feed