It's known that Acetone (like the stuff sold for nail polish removal) can soften the top layer of a 3D print and help smooth it out but I wondered how well it would melt two plastics together. So I dipped a cue tip into the acetone and started rubbing on the edge while pushing toward the gap. It didn't take long to see the improvement in the look of the clip. The gap started to disappear.

|

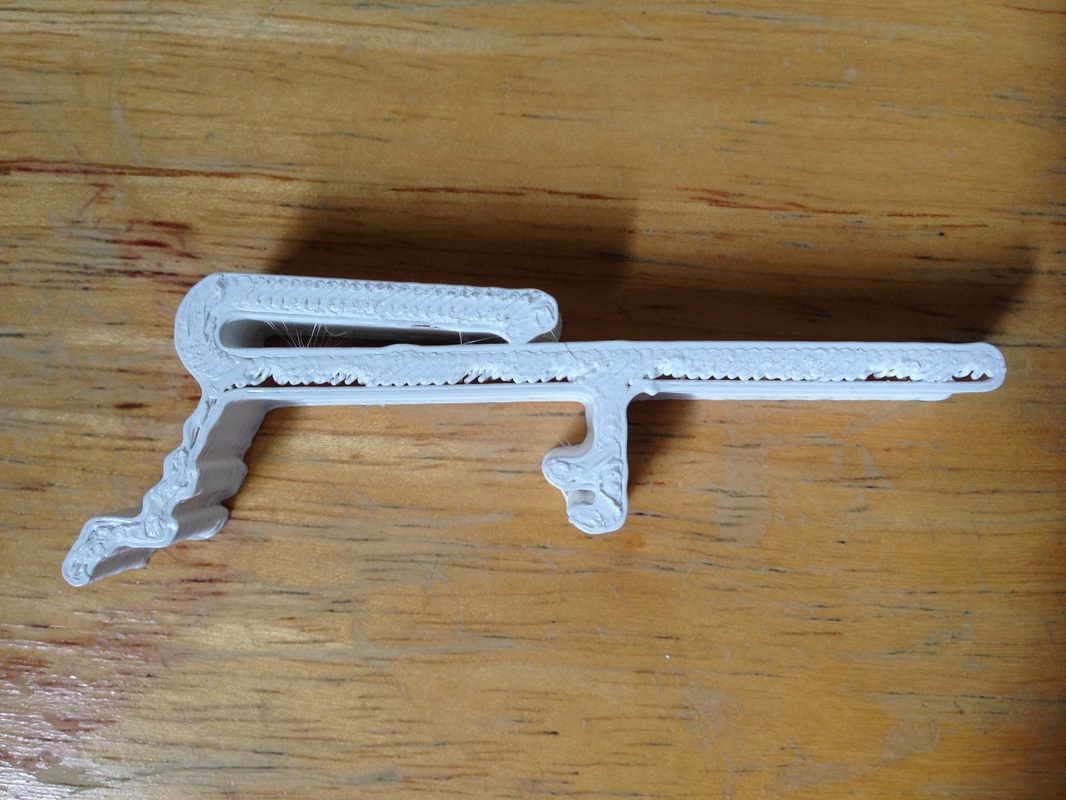

I tried to print some plastic clips with the fastest settings using 0.4 mm height and 10% fill. I also ran the head at the highest speed. The prints came out better than I expected and its a great way to get a prototype print out fast but one drawback is the quality (as you would expect when cutting corners). The picture above left shows the results. The clip had all the key dimensions but the top side of the print had gaps between the outer ring and the inner fill. It affected the clip when snapped in place. The bottom side wall and the inner fill would separate slightly and affect the clips ability to snap in place. So rather than pitch them I tried an experiment. It's known that Acetone (like the stuff sold for nail polish removal) can soften the top layer of a 3D print and help smooth it out but I wondered how well it would melt two plastics together. So I dipped a cue tip into the acetone and started rubbing on the edge while pushing toward the gap. It didn't take long to see the improvement in the look of the clip. The gap started to disappear. A little more rubbing and the edge began to to look filled. The real test can when flexing the clip, and the Acetone did the trick. The clip was much stronger and flexed as expected when snapped in place. The inner and outer plastic had fused together quite well. The clip was obviously stronger and looked better too. I had another print that had split on one of the layers so I applied a little Acetone between the layers and they fused together as if they were never apart. I've heard of people printing pieces of a larger object and then using Acetone to glue them together. Now I understand how well that works. The Davinci 3D printer can print a 7.8" x 7.8" x 7.8" object but now with this Acetone fusing I can print something much bigger.

0 Comments

Leave a Reply. |

Categories

All

Visit previous blog posts in the archives below.

Archives

February 2018

About ChuckChuck has been programming with PIC Microcontrollers since there were only five devices. Now there are over 700 and growing. He also has a lot of fun 3D printing designs using his Davinci 3D printer and TinkerCad software. In this series of blog posts and occasional videos on his YouTube Channel he tries to help you get started with electronics and 3D printing. Disclaimer |

RSS Feed

RSS Feed